Offset bends are used to move a run of conduit from one plane to another. An offset is normally used to bend the conduit around an obstruction, or to relocate the conduit close to a structural member to make it easier to fasten the conduit. Figure 2 shows an example of an offset bend.

Layout.

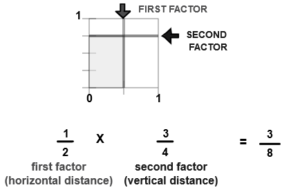

There are several factors that an electrician must determine prior to fabricating an offset. First, he/she must determine the center to center distance of the offset. This dimension is 10″ in Figure 2. Next, he/she must determine the angle of bend to use for the offset. The angle used in Figure 2 is 30º, which is the most popular angle used for bending offsets. After determining these two dimensions, the electrician can then determine the distance between bends needed to make the bends. A trigonometric function, the Cosecant, is used to determine the distance between the centers of the two bends used to make the offset. The Cosecant of an angle is defined as the length of the hypotenuse of a 90º triangle divided by the length of the opposite side of the triangle. Refer to Figure 1.

Figure 1 shows an example of an offset bend. The center to center dimension of the offset is 10″. The angle used to make the bends for the offset is 30º. The Cosecant of 30º is 2.0. The formula used to determine the center to center distance between bends is:

The center to center dimensions of the bends is equal to the desired size of the offset times the cosecant of the angle used to make the bends.

C = 10 x 2, or C = 20″.

30º bends are popular for making offsets, because the cosecant of 30º is 2. Also, most small EMT hand benders are designed so that the bender handle is straight up when a 30º bend has been made with the conduit on the floor. It is also easier to pull wire through a conduit with 30º bends than it is for a conduit with 45º or 60º bends. 45º or 60º bends are sometimes used if the electrician has to bend a large offset in a short distance.

30º bends are too great with most hand benders for offsets less than 4″ center to center. A popular bend for small offsets is 22 1/2º. The table below list several popular bending angles, and the cosecant of the angles.

| Common angles and their cosecants | |||||

| Angle | 10º | 22.5º | 30º | 45º | 60º |

| Cosecant | 5.76 | 2.6 | 2.0 | 1.414 | 1.15 |

Offset Calculator Instructions:

Using this form will enable you to calculate the distance between bends for an offset. You must:

Select the size of the offset desired.

Select the angle to use for the offset.

Select the ‘Calculate’ button.

You will be given the Cosecant of the the angle selected, and the distance between bends to mark the conduit. Remember, the offset is calculated ‘center to center’.

You will be given the Cosecant of the the angle selected, and the distance between bends to mark the conduit. Remember, the offset is calculated ‘center to center’.

| Select the size of the offset: | 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 |

| Select the angle to use: | 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 22.5 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 |

| Cosecant of angle: | |

| Distance between bends: |

How do you bend offset bend?

An offset bend is a type of pipe bend that is offset from the centerline of the pipe. The offset can be to the left or right of the centerline, and is typically used to avoid obstacles or to create a more aesthetically pleasing appearance. To create an offset bend, the first step is to mark the centerline of the pipe on both the top and bottom. Next, the pipe is rotated so that the desired offset is on the top or bottom, and the appropriate amount of material is removed from the side opposite the offset. Finally, the pipe is bent to the desired angle.

There are a few things to keep in mind when creating an offset bend. First, the amount of offset should be limited to no more than 1/3 of the pipe diameter. Second, the minimum wall thickness of the pipe should be maintained. And third, the inside radius of the bend should be at least 3 times the pipe diameter.

If you’re looking to add an offset bend to your pipes, contact a local pipe fitter or welder. They’ll be able to help you determine the best way to create the offset, and can even fabricate the bend for you.

How many degrees of bend are in a 30 degree offset?

How many Bend is used for an offset bend?

In metalworking, an offset bend is a type of bend that is not perpendicular to the workpiece. It is typically used to create a clean, finished look on the edge of a workpiece. The most common type of offset bend is the 90-degree bend, but other angles, such as 45 degrees, can be used.

In order to create an offset bend, a metalworker must first calculate the amount of offset needed. This is typically done by measuring the thickness of the workpiece and the desired offset angle. Once the offset is calculated, the metalworker will use a bending machine to create the bend.

The amount of offset will determine how many bends are needed to create the desired angle. For example, a 90-degree offset bend will require two 45-degree bends. A 45-degree offset bend will require four 22.5-degree bends.

Offset bends are commonly used in metalworking to create a clean, finished look on the edge of a workpiece. By calculating the amount of offset and the number of bends needed, a metalworker can create an offset bend of any desired angle.

How is offset bend calculated?

In order to calculate an offset bend, you will need to know the desired offset distance, the angle of the bend, and the radius of the pipe. To calculate the offset, you will use the following formula:

Offset = (Radius – Offset Distance) / Tan (Angle)

For example, let’s say you have a 4″ pipe with a 3″ radius and you want to make a 90 degree bend with a 1″ offset. To calculate the offset bend, you would use the following equation:

Offset = (3″ – 1″) / Tan (90)

This would give you an offset of 2″.

How do you make an offset?

An offset bend is a type of pipe bend that is used when a pipe needs to be bent in a certain direction, but there is an obstacle in the way. This type of bend is also known as a side-outlet elbow. It is important to note that an offset bend is not the same as a regular elbow, which is used to change the direction of a pipe by 90 degrees. The main difference between the two is that an offset bend has a smaller radius, which allows it to make a tighter turn.

There are two main methods that can be used to create an offset bend. The first is to use a bending machine. This method is typically used for larger projects, as it can be difficult to maneuver a large piece of pipe by hand. The second method is to use a pipe bender. This method is often used for smaller projects, as it is more maneuverable and easier to control.

No matter which method you use, there are a few steps that are always followed when creating an offset bend. First, the pipe is cut to the desired length. Next, the pipe is marked at the point where the bend will start and end. Once the pipe is marked, it is placed in the bending machine or pipe bender. The machine is then turned on and the pipe is slowly bent to the desired angle. Finally, the pipe is cut to the desired length and the ends are welded together.

Offset bends are a common type of pipe bend that are used in a variety of applications. By following the steps outlined above, you can easily create an offset bend using either a bending machine or a pipe bender.

What is the formula for a 45 degree offset?

How do you bend a box offset?

In pipe bending, there are many ways to bend a box offset. The two most common ways are by using a bending machine or by using a jig.

When using a bending machine, the first thing you need to do is to set up the machine. This includes setting the correct die for the machine. The next step is to place the work piece in the machine. After the work piece is in place, the machine is turned on and the metal is heated. Once the metal is heated, the machine is turned off and the work piece is removed. The metal is then placed in the jig and bent to the desired shape.

When using a jig, the first thing you need to do is to create the jig. This includes cutting the metal to the correct size and shape. The next step is to place the work piece in the jig. After the work piece is in place, the jig is heated. Once the jig is heated, the work piece is removed and the metal is bent to the desired shape.

How do you offset backing?

When you are ready to offset your backing, you will need to use a few tools to get the job done. First, you will need to determine the amount you need to offset by. You can do this by measuring the difference between the two lines that you are offsetting. Next, you will need to use a protractor to find the centerline of your pipe. Once you have found the centerline, you will need to make a mark at the point where you need to offset your backing.

Now that you have made your mark, you will need to use a bending spring to offset your backing. To do this, you will need to first find the center of your spring. Once you have found the center, you will need to align it with the mark you made earlier. Next, you will need to bend the spring until it is in the correct position. Finally, you will need to weld the spring in place.

Now that you have offset your backing, you will need to finish the bend. To do this, you will need to use a few tools. First, you will need to use a protractor to find the centerline of your pipe. Once you have found the centerline, you will need to make a mark at the point where you need to finish your bend. Next, you will need to use a bending spring to finish your bend. To do this, you will need to first find the center of your spring. Once you have found the center, you will need to align it with the mark you made earlier. Finally, you will need to weld the spring in place.

How do you do parallel offset?

When you are bending a pipe, the wall of the pipe thins as it is bent. This is due to the process of plastic deformation, in which the molecules in the metal are rearranged and the metal becomes thinner as it is bent. This is why it is necessary to use a die when you are bending a pipe – the die supports the wall of the pipe and prevents it from becoming too thin.

If you want to bend a pipe and have the bend be offset from the center of the pipe, you need to use a process called parallel offset bending. This is done by using two dies, one on each side of the pipe, and offsetting them by the desired amount. As the pipe is bent, the wall is supported by both dies and the pipe is bent to the desired offset.

There are a few things to keep in mind when doing parallel offset bending. First, you need to make sure that the dies are the same size and that they are both at the same offset from the center of the pipe. If they are not, the pipe will not bend evenly and you will not get the desired offset. Second, you need to make sure that the pipe is supported evenly on both sides. If it is not, the pipe will bend unevenly and you will not get the desired offset. Finally, you need to make sure that you are using the correct amount of pressure. Too much pressure will cause the pipe to bend too much and you will not get the desired offset. Too little pressure will cause the pipe to not bend enough and you will not get the desired offset.

If you follow these guidelines, you should be able to successfully bend a pipe with an offset from the center.

How do you offset bend copper?

Copper pipe is a popular material for both plumbing and electrical applications. While it is possible to bend copper pipe by hand, the process is much easier with the help of a pipe bender. A pipe bender is a tool that is specifically designed to bend copper pipe.

There are two types of pipe benders that can be used to bend copper pipe: manual pipe benders and hydraulic pipe benders. Manual pipe benders are less expensive than hydraulic pipe benders, but they require more effort to use. Hydraulic pipe benders are more expensive, but they are much easier to use.

To offset bend copper pipe, start by marking the point on the pipe where you want the bend to start and end. Then, set the pipe in the pipe bender so that the mark for the start of the bend is at the desired location. Slowly bend the pipe until it reaches the mark for the end of the bend.

If you are using a manual pipe bender, you will need to use a lot of force to offset bend the pipe. If you are using a hydraulic pipe bender, the process is much easier. Simply turn on the hydraulic pump and slowly bend the pipe until it reaches the desired angle.

Offset bending is a popular technique for creating drain pipes and other types of piping. It is also possible to use this technique to create electrical conduit. If you are working with electrical conduit, be sure to use a die that is specifically designed for bending electrical conduit.

How is offset pipe measured?

When it comes to measuring offset pipe, there are a few different ways that you can do it. The most common way is to use a ruler or a tape measure. You can also use a protractor if you want to be more precise.

If you’re using a ruler or tape measure, you’ll want to measure from the center of the pipe to the outside edge. To do this, you’ll need to find the center of the pipe first. Once you’ve found the center, you can then measure from there to the outside edge.

If you’re using a protractor, you’ll want to measure the angle of the offset. To do this, you’ll need to find the center of the pipe first. Once you’ve found the center, you can then place the protractor on the pipe and measure the angle.

No matter which method you use, it’s important to be precise when measuring offset pipe. That way, you can be sure that your pipe will fit perfectly in your project.

Conclusion

We hope this blog post “Assured Grounding” has helped clear up any confusion you may have had. If you have any further questions, feel free to reach out to us and we would be happy to help!

Hey, check out: Segment Bends

Today sponsors are Localhandymantulsa.com , Sprinkler Repair Long Island , Mailboxrepairtulsa.com , Chestercountytowingservices.com and Huttotxroofrepair.com. Always providing the best services in town.