Sample method to bend 3-1/2″ rigid conduit around a storage tank with a diameter of 160 feet.

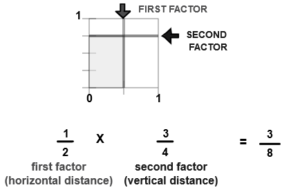

Segment bending is a method of bending conduit by making several small bends to produce one larger bend. The method on this page illustrates a technique for bending a 3-1/2″ rigid conduit around a tank with a 160′ diameter.

The steps for calculating a large radius segment bend are:

- Determine the radius of the desired bend.

The following procedure illustrates the procedure to bend a length of 3-1/2″ rigid conduit around a storage tank with an 80′ radius, or a 160′ diameter.

First, find the circumference of the tank.

Diameter in inches, with 2 strut, 1 on each side, plus 1 conduit diameter, or 1/2 for each side, = 160 x 12 + 1-5/8 x 2 + 2 x 2 = 1925.625″

Circumference = Pi x Diameter = 3.14159265 x 1925.625 = 6,049.53″. This is the total length of conduit needed to complete the bending angle of 360 degrees to go all the way around the tank. A 10′ length of 3-1/2″ rigid conduit without the coupling is 9′ 10-1/4″ = 118-1/4″. The number of conduit required to go all the way around the tank, or 360 degrees, is 6,049.53 / 118.25 = 51.16.

Divide the total angle to go around the tank, 360 by the number of conduits required, 51.16, to get the angle required to bend each length of conduit. 360 / 51.16 = 7.04 degrees for each length of conduit.

- Determine the number of segments desired or required for the completed bend.If a length of conduit is going to be bent to such a small angle, it is practical to only make 2 or 3 bends on each length of conduit.

- Determine the Developed Length of the bend.Developed length (DL) is the length of conduit that is actually bent. The formula to calculate the developed length of a bend is: Developed length (DL) is equal to the centerline radius (R) of the bend times the angle (A) of the bend times 0.01745. DL = R x A x 0.01745The radius of the tank plus the strut and conduit is 962.8125″ The developed length for a 7.04 degree bend with a 962.8125″ radius is 7.04 x 962.8125 x 0.01745 = 118.28″.

DL = 7.04 x 962.8125 x 0.01745 = 118.28″. You can see that this is one length of 3-1/2 rigid conduit.

If you want to make the bend with 1 bend, you can make on 7 degree bend in the center of the conduit.

More realistically, partly for purposes of strapping the conduit, and NEC requirements for distance from any junction boxes to straps, I would make 2 bends of about 3.5 degrees at about 30″ and 90″ on the length of conduit, at approximately the 1/3 and 2/3 distances on the conduit.

You could select a larger number of bends, but I think it would be more difficult to bend to a smaller angle, although the bends will look smoother.

What is the formula for concentric bends?

Concentric bends are a type of pipe fitting used to connect two pipes of different diameters. The formula for concentric bends is:

D1 x D2 x T

Where:

D1 = the outside diameter of the smaller pipe

D2 = the outside diameter of the larger pipe

T = the thickness of the wall of the pipe

The formula for concentric bends is used to calculate the dimensions of the bend. The bend is then cut to the correct size and welded in place.

Concentric bends are used in a variety of applications, such as connecting two pipes of different diameters, or connecting a pipe to a valve or fitting.

There are a few things to keep in mind when using the formula for concentric bends. First, the outside diameter of the smaller pipe must be less than the outside diameter of the larger pipe. Second, the wall thickness of the pipe must be taken into account.

When using the formula for concentric bends, it is important to use the correct dimensions. This will ensure a proper fit and prevent any leaks.

What are the different types of bend?

Pipe bending is a vital process in a variety of industries, from plumbing to automotive manufacturing. There are many different types of bends that can be used to achieve the desired results, and each has its own advantages and disadvantages.

The most common types of bends are the 90-degree bend, the U-bend, and the J-bend. The 90-degree bend is the simplest and most common type of bend, and is typically used when a change in direction is needed but no specific shape is required.

The U-bend is more complex, and is used when a more pronounced change in direction is needed, such as when connecting two pieces of pipe at right angles. The J-bend is the most complex type of bend, and is used when a very specific shape is required, such as when creating a custom pipe fitting.

Each of these types of bends has its own advantages and disadvantages that should be considered before choosing which one to use. The 90-degree bend is the simplest and most common, so it is typically the cheapest and quickest to produce. However, it can cause friction and turbulence in the flow of liquids or gases, and is not suitable for use in high-pressure applications. The U-bend is more complex and can be more expensive and time-consuming to produce, but it eliminates friction and turbulence and is ideal for high-pressure applications.

The J-bend is the most complex and can be the most expensive and time-consuming to produce, but it provides the most precise control over the shape of the pipe and is ideal for use in custom applications.

When choosing which type of bend to use, it is important to consider the specific needs of the application. The 90-degree bend is the simplest and most common, so it is typically the cheapest and quickest to produce; however, it can cause friction and turbulence in the flow of liquids or gases, and is not suitable for use in high-pressure applications.

The U-bend is more complex and can be more expensive and time-consuming to produce, but it eliminates friction and turbulence and is ideal for high-pressure applications. The J-bend is the most complex and can be the most expensive and time-consuming to produce, but it provides the most precise control over the shape of the pipe and is ideal for use in custom applications.

What is concentric bending?

What is radial bending?

Radial bending is a type of pipe bending that is typically used for creating circular or near-circular shapes. This process can be used to create a wide range of shapes, including curves and circles, and is often used in the construction of pipes and tubing.

Radial bending gets its name from the fact that the bending force is applied to the pipe at a perpendicular (or “radial”) angle. This perpendicular force is what gives the pipe its shape. Radial bending is a relatively simple process, and can be done with a variety of different machines.

One of the benefits of radial bending is that it can be used to create very tight bends. This is due to the fact that the force is applied directly to the pipe, rather than at an angle. This makes radial bending ideal for creating pipes and tubing with small diameters.

Another benefit of radial bending is that it is a very versatile process. It can be used to create a wide range of shapes, including curves and circles. This makes radial bending a popular choice for use in the construction of pipe and tubing.

If you are in the market for a machine to do radial bending, there are a few things you should keep in mind. First, you will need to decide what type of machine you need. There are several different types of radial bending machines, each of which is designed for a specific type of pipe.

Next, you will need to decide on the size of the machine. Radial bending machines come in a variety of sizes, and you will need to choose one that is appropriate for the size of the pipe you will be working with.

Finally, you will need to decide on the material you will be using. Radial bending machines can be made from a variety of materials, including steel, aluminum, and even plastic. Each material has its own advantages and disadvantages, so you will need to choose the one that is best suited for your needs.

No matter what your needs are, radial bending is a versatile process that can be used to create a wide variety of shapes. If you are in the market for a machine to do radial bending, keep these things in mind to ensure you choose the right one for your needs.

How do you calculate segmented bends?

When it comes to metalworking, one of the most important things to know is how to calculate segmented bends. This is because segmented bends are often used in order to create objects with a high degree of accuracy. There are a few different methods that can be used in order to calculate segmented bends, and the method that you use will depend on the type of object that you are trying to create. In this article, we will take a look at a few different methods that can be used in order to calculate segmented bends.

The first method that we will take a look at is the use of a protractor. A protractor can be used in order to measure the angle of the bend that you are trying to create. In order to do this, you will need to place the protractor on the object that you are trying to bend. Once you have done this, you will need to align the zero mark on the protractor with the centerline of the object. After you have done this, you will need to read the angle that is indicated on the protractor. This angle will be the angle of the segmented bend that you are trying to create.

Another method that can be used in order to calculate segmented bends is the use of a template. This method is often used when the object that you are trying to create is too small to accurately measure with a protractor. In order to create a template, you will need to create a paper template of the object that you are trying to create. Once you have done this, you will need to place the template on the object that you are trying to bend. After you have done this, you will need to mark the template at the point where you want the bend to occur. Once you have done this, you will need to measure the distance between the two marks that you have made. This distance will be the length of the segmented bend that you are trying to create.

The last method that we will take a look at is the use of a digital protractor. This method is similar to the use of a regular protractor, but the digital protractor will give you a more accurate reading. In order to use a digital protractor, you will need to place the protractor on the object that you are trying to bend. Once you have done this, you will need to align the zero mark on the protractor with the centerline of the object. After you have done this, you will need to press the button on the digital protractor that will take a reading. This reading will be the angle of the segmented bend that you are trying to create.

These are just a few of the different methods that can be used in order to calculate segmented bends. In most cases, the method that you use will be determined by the type of object that you are trying to create.

What are the 4 kinds of bend defects?

Bend defects are often the result of incorrect material properties, incorrect process conditions, or a combination of both. There are four main types of bend defects:

- Wrinkles

- Cracks

- Undercut

- Overcut

Wrinkles are the most common type of bend defect and are caused by a lack of tension in the material being bent. This can be due to incorrect material properties, incorrect process conditions, or a combination of both.

Cracks are another common type of bend defect and are caused by too much tension in the material being bent. This can be due to incorrect material properties, incorrect process conditions, or a combination of both.

Undercut is a type of bend defect that is caused by the material being bent not being able to make full contact with the die. This can be due to incorrect material properties, incorrect process conditions, or a combination of both.

Overcut is a type of bend defect that is caused by the material being bent making too much contact with the die. This can be due to incorrect material properties, incorrect process conditions, or a combination of both.

Bend defects can often be avoided by using the correct material properties and process conditions for the application.

What does 5D bend mean?

In pipefitting, the term “5D bend” refers to a type of pipe elbow that is used to make a five-dimensional turn. This type of bend is typically used when space is limited and a standard elbow is not possible.

A 5D bend is made by first creating a three-dimensional bend, then adding two more bends to create the five-dimensional turn. This type of pipe elbow is often used in tight spaces, such as in between walls or in corners. It is also commonly used in automotive applications, such as in exhaust systems.

While a 5D bend may be more expensive than a standard elbow, it can save time and money in the overall installation. In addition, it can provide a better fit and a cleaner look in some applications.

What is segment in pipe?

Conclusion

We hope this blog post “Segment Bends” has helped clear up any confusion you may have had. If you have any further questions, feel free to reach out to us and we would be happy to help!

Hey, check out: StackedKicksSample

Today sponsors are Localhandymantulsa.com , sprinklerrepairlongisland.com , Mailboxrepairtulsa.com , Chestercountytowingservices.com and Huttotxroofrepair.com. Always providing the best services in town.