What Size Drill Bit For 5/16 Bolt? When it comes to finding the right size drill bit for a 5/16 bolt, there are a few things you need to take into consideration. The first is the diameter of the hole that needs to be drilled. The second is the depth of the hole. And the third is the type of material you’ll be drilling into.

For most applications, a 1/4″ drill bit will suffice for drilling a 5/16″ hole. However, if you’re working with thicker materials or need a deeper hole, you may need to go up to a 3/8″ drill bit. And if you’re working with particularly hard materials, such as stainless steel, you may even need to go up to a 1/2″ drill bit.

No matter what size drill bit you end up needing, always make sure that it’s sharp and in good condition before beginning your project. A dull or damaged drill bit can cause problems, such as stripping out the threads on your bolt or breaking off inside the hole.

What size drill bit do I need for a 5/16 24?

When it comes to finding the right drill bit size for a 5/16 24, there are a few things that you need to take into consideration. First, you need to make sure that the drill bit is compatible with the material that you’re going to be drilling through. Second, you need to make sure that the drill bit is long enough to reach the desired depth. And finally, you need to make sure that the drill bit has a diameter that is small enough to create a hole that is 5/16 24 in size.

Now that we’ve gone over what you need to keep in mind when choosing a drill bit for a 5/16 24, let’s take a look at some of the most common sizes and see which one would be best for your needs. For thin materials like wood or plastic, a 3/32 inch drill bit will do just fine. If you’re working with thicker materials like metal or concrete, then you’ll want to use a 1/8 inch or larger drill bit.

And there you have it! Now you know everything there is to know about finding the right size drill bit for a 5/16 24. Just remember to take into account the material you’re working with and the desired depth, and you’ll be good to go.

What diameter is a 5/16 bolt?

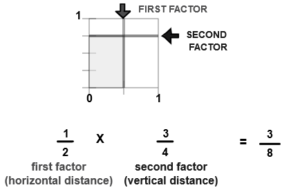

When it comes to determining the diameter of a 5/16 bolt, there are a few things that you need to take into account. The first is the threads per inch, which in this case is 18. This means that there are 18 threads per inch on the 5/16 bolt. The second thing you need to know is the major diameter, which is the distance between the outermost threads on the bolt.

In this case, the major diameter of a 5/16 bolt is 0.3125 inches. Finally, you need to know the pitch diameter, which is the distance between adjacent threads on the bolt. For a 5/16 bolt, the pitch diameter is 0.293 inches. With all of this information in mind, you can now determine that the diameter of a 5/16 bolt is 0.3125 inches + (0.293 inches / 2) = 0.35425 inches.

What size drill bit do I need for a 5/16 rivet nut?

Is 5/16 The same as 8mm drill bit?

When it comes to drill bits, the metric and imperial system can be very confusing. In the United States, we use inches while most of the world uses millimeters. This can make shopping for drill bits online or in other countries quite difficult. So, what is the answer to the question: Is 5/16 The same as 8mm drill bit?

The simple answer is no. 5/16 is not the same as 8mm. The reason for this is because they are two different units of measurement. 5/16 is an imperial unit while 8mm is a metric unit. They are not interchangeable.

Now that we know they are not the same, let’s look at how they differ. The biggest difference between these two units is their size; 8mm is actually slightly larger than 5/16″. A more accurate way to compare these two sizes would be to say that 8mm is equivalent to about 21/64″.

When it comes to buying drill bits, it’s important that you know which system your country uses so that you can purchase the right size bit for your project!

How do I know what size drill bit to use?

One question that we get a lot here at the hardware store is “How do I know what size drill bit to use?” It’s a good question, and one that has a pretty simple answer. Here’s a quick guide to help you select the right drill bit for your project.

The first thing you need to do is determine the size of the hole you need to drill. For most projects, you’ll want to stay within 1/8″ of the final size of the hole. So, if you’re looking to make a 1/2″ hole, you’ll want to use a 7/16″ drill bit.

Once you’ve selected the appropriate bit size, it’s time to start drilling! Begin by making a pilot hole with your chosen drill bit. This will help ensure that your final hole is straight and true. If necessary, increase the size of your pilot hole until it’s just big enough for your final drill bit to fit through easily.

Now simply insert your larger drill bit into the pilot hole and start drilling! Remember to go slowly and apply gentle pressure – especially when breaking through into the second side of your material.

And that’s all there is too it! With these tips in mind, selecting the right drill bit size for your project should be a breeze.

How big should a hole be for a bolt?

When it comes to holes for bolts, the size of the hole is extremely important. If the hole is too small, the bolt will not be able to fit through and if the hole is too big, the bolt will be loose and could potentially fall out. So, how can you determine what size hole to make?

There are a few things that you will need to take into consideration when deciding on the size of the hole. The first is the diameter of the bolt. The second is the thread pitch, which is determined by how many threads there are per inch. And lastly, you will need to know whether or not you will be using a washer with your bolt.

Once you have all of this information, you can use a chart to determine what size drill bit you will need to use to create your hole. For example, if you are using a 1/4-inch diameter bolt with a 20 thread pitch and no washer, then you would need to use a 7/32-inch drill bit.

Keep in mind that it is always better to err on the side of making your hole slightly too big rather than making it too small. This way, you can avoid having any issues with your bolts not being able to fit properly.

How much bigger should the bolt hole be than the bolt?

When it comes to deciding how much bigger the hole should be than the bolt, there are a few things you need to take into account. The first is the type of material the hole will be drilled in. Softer materials, like wood, will require a smaller margin of error than harder materials, like metal.

The second thing you need to consider is the environment in which the hole will be used. If it’s a critical fastener in a structure that will see a lot of vibration or stress, you’ll want to err on the side of making the hole slightly larger.

Finally, you need to think about how easy it will be to replace the bolt if necessary. If you’re working with a difficult material or tight tolerances, making the hole slightly larger can give you some wiggle room when it comes time to remove and replace the bolt.

In general, most experts recommend making the hole 1/16″ larger than the diameter of the bolt being used. This gives enough clearance for easy installation and removal, while still ensuring a snug fit that won’t allow for excessive movement.

Of course, the best way to get an accurate measurement is to use a drill bit that matches the diameter of the hole you want to create. This ensures you’ll end up with a perfect fit, no matter what material or environment you’re working with.

Are bolt holes always clearance holes?

No, bolt holes are not always clearance holes. A clearance hole is simply a hole that is big enough for the object to pass through. A bolt hole, on the other hand, is a specific type of hole designed to accommodate a particular type of fastener (usually a screw or nail).

There are many different types of bolt holes, but the most common are countersunk and counterbored. Countersunk holes are tapered so that the head of the fastener can be flush with or below the surface of the material. Counterbored holes are drilled all the way through the material and then enlarged at one end to create a countersink.

Both types of bolt holes must be slightly larger than the shank of the fastener in order to allow it to pass through. This gap is known as “clearance.” The amount of clearance needed will depend on factors such as tooling tolerances and finish requirements.

In general, it’s best to err on the side of too much rather than too little clearance. If there isn’t enough room for the fastener, it can cause binding and make it difficult (or even impossible) to insert or remove. On the other hand, too much clearance can result in loose joints and potentially even failure.

When in doubt, consult the engineering drawings or specifications for the particular project you’re working on. They will list the required tolerances for each hole.

How much tolerance does a bolt hole need?

When it comes to machining, one of the most important factors to consider is tolerance. This is especially true when it comes to drilling bolt holes. How much tolerance does a bolt hole need? The answer may surprise you.

In general, a bolt hole should have a clearance that is equal to or slightly larger than the diameter of the bolt being used. For example, if you are using a 1/2″bolt, the hole should have a clearance of at least 1/2″. If possible, it is always best to err on the side of caution and drill slightly larger holes. This will ensure that there is enough room for the bolts to be inserted and tightened without issue.

It is also important to note that different materials will require different tolerances. Softer materials like wood can usually get away with less tolerance than harder materials like metal. This is because softer materials are more forgiving and can expand or contract slightly without causing problems. Harder materials are not as forgiving and need to be machined with greater precision in order to avoid issues.

When in doubt, always consult with a qualified machinist or engineer before beginning any project. They will be able to advise you on the proper tolerances for your particular application. With their help, you can be sure that your bolt holes will be just the right size.

How deep should the bolt be drilled?

When it comes to drilling holes for bolts, the general rule of thumb is that the hole should be drilled to a depth that is 1.5 times the length of the bolt. So, if you are using a 3-inch long bolt, then you would drill a hole that is 4.5- inches deep. This ensures that the bolt will have enough grip and holding power.

Of course, there are always exceptions to this rule. If you are working with very soft materials, then you may not need to drill as deep of a hole. Conversely, if you are working with very hard materials, then you may need to drill an even deeper hole.

Ultimately, it is important to use your best judgement and consult with someone who has experience if you are unsure about how deep to drill your hole. With a little bit of care and attention, you can ensure that your bolts will stay put and do their job properly!

Should bolts face up or down?

There are a lot of opinions out there about whether bolts should face up or down. Some say that bolts should face up so that the person driving can see them and avoid them. Others say that bolts should face down so that they don’t get in the way. So, which is it?

Well, there’s no right or wrong answer to this question. It really depends on your preference and what you’re trying to achieve with your bolt pattern. If you’re looking for a more aesthetically pleasing look, then facing the bolts up may be the way to go. However, if you’re worried about the bolts getting in the way, then facing them down may be a better option.

At the end of the day, it’s really up to you how you want to orient your bolts. Just make sure that they’re tight and secure before you hit the road!

How do you fix a bolt hole that is too big?

There are a few ways to fix a bolt hole that is too big. One way is to use a product called JB Weld. This product can be found at most hardware stores. First, clean the area around the hole with a wire brush. Then, mix the JB Weld according to the instructions on the package. Next, apply the JB Weld around the outside of the hole. Finally, let it dry for 24 hours before putting in a new bolt.

Another way to fix this problem is to use epoxy putty. This can also be found at most hardware stores. First, clean the area around the hole with a wire brush or sandpaper. Next, mix together equal parts of the putty according to the instructions on the package. Then, apply it to the hole and let it dry for the amount of time specified on the package.

If you have a much larger hole, you may need to use a patch. For this, you will need to buy a sheet of metal that is slightly larger than the hole. First, clean the area around the hole with a wire brush or sandpaper. Next, cut out a piece of the metal sheet that is slightly larger than the hole. Then, bend the edges of the metal sheet so that they fit snugly against the sides of the hole. Finally, use bolts or screws to secure the patch in place.

No matter which method you choose, be sure to follow all instructions carefully and take all necessary safety precautions.

Should you torque the bolt or the nut?

There’s a lot of debate out there about the best way to torque a bolt. Should you torque the bolt or the nut? The answer, it turns out, is a little bit of both.

In order to properly torque a bolt, you need to first tighten the nut until it’s snug. Then, you should torque the bolt to the appropriate level. This will ensure that the joint is secure and won’t come loose over time.

Some people will tell you that it’s best to just torque the bolt and not bother with the nut at all. However, this can lead to problems down the line. If you don’t properly secure the nut, it can work its way loose and cause all sorts of issues.

The bottom line is that you should always torque both the bolt and the nut when assembling a joint. This will give you the strongest and most reliable connection possible.

How many threads should be left on a bolt?

When it comes to how many threads should be left on a bolt, there is no definitive answer. It depends on a variety of factors, such as the size and type of the bolt, the material it is made from, and the application it will be used for. In general, however, most bolts can accommodate between two and four threads.

There are several things to consider when deciding how many threads to leave on a bolt. The first is the size of the bolt. A small bolt may only need two or three threads, while a larger one may need four or more. The second factor is the type of bolt.

Machine screws and other types of bolts that are subject to high loads or frequent use may require more threads for added strength and stability. Finally, the application the bolt will be used for must be taken into account. If it will be exposed to extreme conditions (e.g., high temperatures or corrosive environments), then more threads may be needed to ensure a long lifespan.

In most cases, leaving two or three threads on a bolt should suffice. However, if you are unsure, it is always best to consult with an expert before making your final decision.

What keeps a bolt in place?

When we think about the things that keep our world together, we usually think of things like love and friendship. But there are other, more literal things that keep our world together too – like bolts! Ever wondered how a bolt keeps everything in place? Read on to find out…

Bolts are one of the most important pieces of hardware in the world. They’re used to fasten two or more objects together, and can be found in everything from bridges to buildings to cars. But how do they work?

It all has to do with friction. When a bolt is tightened, the threads inside the bolt grip onto the threads of the nut. This creates friction between the two surfaces, which prevents them from moving relative to each other.

But why does this create a secure connection? After all, you can unscrew a bolt just by turning it in the opposite direction. The key is that it takes quite a bit of force to overcome that friction and start turning thebolt. That’s why bolts are so good at keeping things together – it’s very difficult to accidentally loosen them.

Of course, there are different types of bolts for different purposes. Some bolts are designed to be loosened and removed easily, while others are meant to be permanent fixtures. But regardless of their purpose, they all work by taking advantage of friction to keep things secure.

So next time you see a bolt, remember that it’s more than just a piece of hardware – it’s an essential part of the world around us.

Conclusion

We hope this blog post “What Size Drill Bit For 5/16 Bolt?” has helped clear up any confusion you may have had. If you have any further questions, feel free to reach out to us and we would be happy to help!

Hey, check out: What Size Drill Bit Do I Need to Tap a 3/8 Hole?

Today sponsors are Localhandymantulsa.com , sprinklerrepairlongisland.com , Mailboxrepairtulsa.com , Chestercountytowingservices.com and Huttotxroofrepair.com. Always providing the best services in town.