Concentric bends are a set of conduit bends that have a common center point, but have different centerline radii.

Figure 1 shows three concentric bends produced from 2″ rigid conduit. Conduit 1 has a centerline radius of 20″. Conduit 2 has a centerline radius of 24 3/8″. Conduit 3 has a centerline radius of 28 3/4″.

The outside diameter of 2″ rigid conduit is approximately 2 3/8″. The conduits in this example have a 2″ separation between conduits.

The bends in this example are produced by making 15 evenly spaced bends of 6º each, to produce a 90º bend.

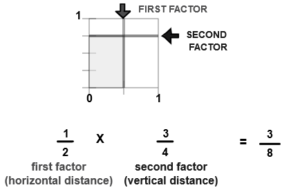

Figure 2 is a close-up of one of the 15 x 6º segment bends made to complete one of the three concentric bends.

Line ‘c’ represents one of the 15 segments used to bend Conduit 1.

The formula used to find the length of line ‘c’ is:

c = centerline radius of the bend x (2 x (tanØ / 2)), or 2 x (tanØ / 2) can be simplified to tanØ. Therefore,

c = centerline radius of bend x tanØ.

The centerline radius of Conduit 1 is 20″. Angle Ø is 6º. Then: c = 20 x tan(6º) Tan(6º) = .105 c = 20 x .105. c = 2.10″ = 2 1/8″.

The distance between bends for Conduit 1 = 2 1/8″.

Substitute the radii of Conduit 2 and Conduit 3 in the formula to find the center to center distance between bends for these conduits.

For Conduit 2: c = 24.375 x tan(6º). c = 24.375 x .105. c = 2.56″ = 2 1/2″.

The distance between bends for Conduit 2 = 2 1/2″.

For Conduit 3: c = 28.75 x tan(6º). c = 28.75 x .105. c = 3.02″ = 3″.

The distance between bends for Conduit 3 = 3″.

The length of conduit required to produce the bend is called the developed length.The developed length(DL) is equal to the centerline radius of the bend times the angle of the bend x 0.0175.

For Conduit 1: DL = 20 x 90 x 0.0175. dl = 31.5″.

For Conduit 2: DL = 24.375 x 90 x 0.0175. dl = 38.39″.

For Conduit 3: DL = 28.75 x 90 x 0.0175. dl = 45.28″.

Segment bends can be made from any number of bends, or segments. The closer together the bends are made, the smoother the total bend will look.

Notice, that as a matter of practicability, the distance between bends must be greater than the length of each bent segment. If the distance between bends is not greater than the length of each bent segment, select a lesser number of bends to make, and/or a different centerline radius.

Segment Bends contains more information about this type of bend, and also has a segment bending calculator for calculating the layout and the developed length of segment bends.

How do you measure concentric bends?

If you’re looking to measure a concentric bend, there are a few different ways you can go about doing so. Here are a few methods that you can use to get the most accurate measurement possible:

- Use a micrometer: This is probably the most accurate way to measure a concentric bend. Just place the micrometer on the outside of the bend and take your reading.

- Use a caliper: This method is also quite accurate. Simply place the caliper on the outside of the bend and take your reading.

- Use a ruler: This is the least accurate method, but it can still give you a general idea of the size of the bend. Just measure from the center of the bend to the outside edge.

How do Emts make concentric bends?

If you are an EMT, you know that one of the most important things you can do is make concentric bends. But how exactly do you do this? Let’s take a look.

First, you need to find a pipe that is the same diameter as the one you will be bending. Then, you need to cut the pipe in half. Next, you need to mark the pipe at the point where you want the bend to start and end. Once you have done this, you need to heat the pipe until it is glowing red.

Now, it’s time to start bending the pipe. To do this, you need to apply pressure to the pipe at the point where you want the bend to start. As you apply pressure, you need to slowly rotate the pipe. Continue applying pressure and rotating the pipe until you reach the point where you want the bend to end.

Once you have reached the end of the bend, you need to allow the pipe to cool. Once it has cooled, you will have a perfect concentric bend!

What is a segment bend?

What are the common types of bends?

There are many types of bends that can be used when pipefitting, each with their own advantages and disadvantages. The most common types of bends are the 90-degree elbow, the 45-degree elbow, the 180-degree return bend, and the tee.

The 90-degree elbow is the most commonly used type of bend. It is used to change the direction of flow in a piping system, and is available in both welded and seamless varieties. The 45-degree elbow is also used to change the direction of flow, but is less common than the 90-degree elbow. The 180-degree return bend is used to connect two pieces of pipe that are going in the same direction. The tee is used to connect three pieces of pipe, two of which are going in the same direction.

Each of these types of bends has its own advantages and disadvantages. The 90-degree elbow is the most common because it is the most versatile. The 45-degree elbow is less common because it can only be used when space is limited. The 180-degree return bend is less common because it is more expensive. The tee is less common because it can only be used when three pieces of pipe need to be connected.

What is an offset bend?

If you have ever seen a pipe that is bent at an angle, then you have seen an offset bend. An offset bend is a type of pipe bend that is used to change the direction of a pipe. The most common use for an offset bend is to connect two pipes that are not in line with each other.

Offset bends are classified by their angle and their radius. The angle is the angle between the two pipes that are being connected. The radius is the distance from the center of the offset bend to the center of the pipe. There are two types of offset bends, long radius offset bends and short radius offset bends.

Long radius offset bends have a radius that is 1.5 times the diameter of the pipe. This type of offset bend is used when there is a need for a large amount of movement in the pipe. Short radius offset bends have a radius that is equal to the diameter of the pipe. This type of offset bend is used when there is a need for a small amount of movement in the pipe.

Offset bends are used in a variety of applications, such as in HVAC systems, plumbing systems, and in process piping. They are a versatile type of pipe bend that can be used in many different situations.

How do you calculate a segment bend?

When it comes to ductwork, one of the most important things to consider is the segment bend. This is because the segment bend will determine how well the airflow will be able to move through the ductwork. There are a few different ways that you can calculate a segment bend, but the most common way is to use the following formula:

Bend Diameter = (Segment Length * 12) / Bend Angle

For example, let’s say that you have a segment of ductwork that is 10 feet long and you want to make a 45 degree bend. Using the formula above, you would calculate the bend diameter as follows:

Bend Diameter = (10 * 12) / 45

This would give you a Bend Diameter of 26.667 inches.

Another way to calculate a segment bend is to use the following formula:

Bend Diameter = (Segment Length * 24) / (Bend Angle * 2)

For example, let’s say that you have a segment of ductwork that is 10 feet long and you want to make a 45 degree bend. Using the formula above, you would calculate the bend diameter as follows:

Bend Diameter = (10 * 24) / (45 * 2)

This would give you a Bend Diameter of 53.333 inches.

As you can see, there are a few different ways that you can calculate a segment bend. The most important thing is to use the correct formula for the type of ductwork you are using.

What is the formula for 90 degree bend?

There are a few different formulas that can be used when it comes to calculating a 90 degree bend, and which one you use will depend on the specific situation. If you know the radius of the bend, then you can use the formula: radius x 3.1416 = circumference. This will give you the length of the pipe that you need in order to make a 90 degree bend.

Another formula that can be used is the one that takes into account the diameter of the pipe. In this case, you would use the formula: diameter x 3.1416 = circumference. This also gives you the length of the pipe that you need in order to make a 90 degree bend.

One last formula that can be used is the one that takes into account the width of the pipe. In this case, you would use the formula: width of the pipe x 3.1416 = circumference. This also gives you the length of the pipe that you need in order to make a 90 degree bend.

So, as you can see, there are a few different formulas that can be used in order to calculate the length of pipe needed for a 90 degree bend. Which one you use will depend on the specific situation.

How do you calculate bend radius?

Bend radius is the minimum radius a pipe can be bent without damaging it. The smaller the radius, the greater the stress on the pipe and the more likely it is to crack or break. There are a few different ways to calculate bend radius, but the most common is to use the formula R = D/t. R is the radius, D is the diameter of the pipe, and t is the thickness of the pipe. This formula will give you the minimum radius you can bend the pipe without damaging it.

How do you measure pipe bends?

Conclusion

We hope this blog post “Concentric Bends” has helped clear up any confusion you may have had. If you have any further questions, feel free to reach out to us and we would be happy to help!

Hey, check out: Center Of Bend

Today sponsors are Localhandymantulsa.com , Sprinkler Repair Long Island , Mailboxrepairtulsa.com , Chestercountytowingservices.com and Huttotxroofrepair.com. Always providing the best services in town.